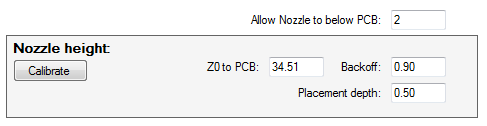

When you calibrate the nozzle height (Z values), you use the Nozzle height subwindow on the Basic Setup page:

Calibrate button starts the PCB surface and backoff values measurement.

Z0 to PCB is the probed value to the PCB surface.

Backoff is the value up from any probed height where the needle still barely touches the item it is probing; in this case, the PCB surface. This is measured together with the PCB surface height.

Placement depth is the value down from backoff height that is used for placement and pick up operations. This value should normally be less than backoff and greater than 0. There is no check for this, as “non-sensible” values do make sense in some special cases.

Note1: On the first component of its type (on a tape, if the pickup/place Z values are not known) the Z values are probed, i.e. the needle comes down all the way triggering the switch, so it finds the values. After this, the placement depth is used.

Note2: When placing components, the placement force is surprisingly high. On big machines, the force is typically few Newtons (200g to 500g). Don’t be too cute with these settings.

Allow Nozzle to Below PCB: This is a safeguard value, preventing the software doing stupid things in case of an error. You might find a need to tune the value. For example, if the PCB is 1.6mm, and shallow component is 0.2mm high and placement depth is 1mm, the nozzle goes down 1.4mm + 1mm = 2.4mm. With the default value, this would cause a warning text box to come up.