(The instructions for earlier version are here.)

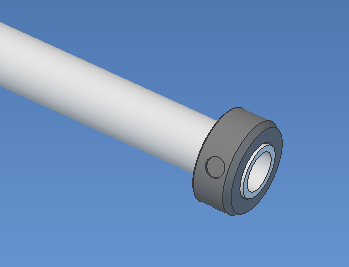

Take the pick up tube and attach one SCCN8-x collar to the end of it, as shown. (Depending on availability, the exact collar type can change.)

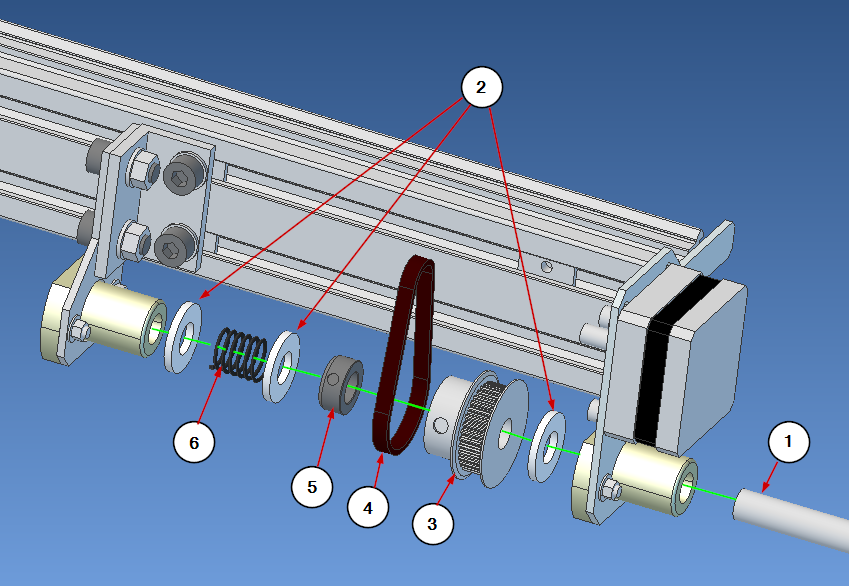

Insert the tube to the lower bearing as shown. Between the bearings, insert the following in the this order: M8 nylon washer; 36 teeth pulley (note the orientation); 60 teeth belt loop; SCCN8-x collar, M8 nylon washer; spring; M8 nylon washer:

- Pick-up tube

- M8 nylon washer x 3

- GT2-36 pulley

- GT2-122 belt loop

- SCCN8-x collar x 1

- spring

Tighten the pulley screws to hold the tube in place so, that there is 3-4mm free movement left, before the low bearing and the collar would hit.

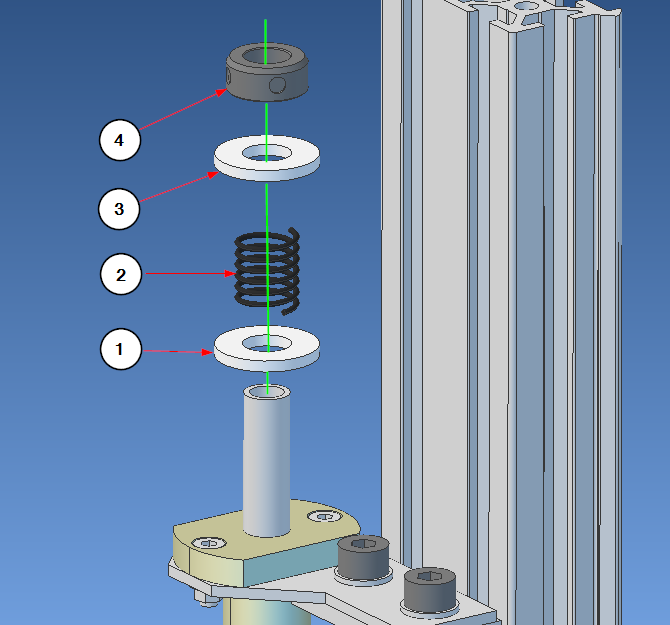

On top of the tube, install M8 nylon washer, a spring, another nylon washer and SCCN8-x collar as shown. If needed, move the upper bearing down.

- M8 nylon washer

- spring

- M8 nylon washer

- SCCN8-x collar

The springs will adjust the force that the pickup nozzle pushes down on parts. There is provision for adding or reducing the force that gravity gives us. You can adjust this later, if needed. For now, tighten the collars in position so, that neither spring is compressed.

Rotate and slide the tube in the bearings and adjust the top bearing so, that the movement is smooth and free. Tighten the middle plate and the bracket in place and once more, check that the tube rotates freely and can easily move up and down.

Slide the 16 teeth pulley to the motor shaft, base down. Slide the motor towards the tube so that you can get the belt in place. Pull the motor back tightening the belt slightly. Find a compromise where the belt is somewhat tight, and there is no slack in the bearings against the belt. (There is still some slack in the bearings sideways; we’ll deal with this later.) The tube should still move freely up and down. Tighten the motor in place. Rotate the tube a few times to allow the small pulley to find the correct height and tighten the pulley to the motor shaft.

You want the tube to be firm, easlily rotated and needing only slight force to move up a few mm’s.